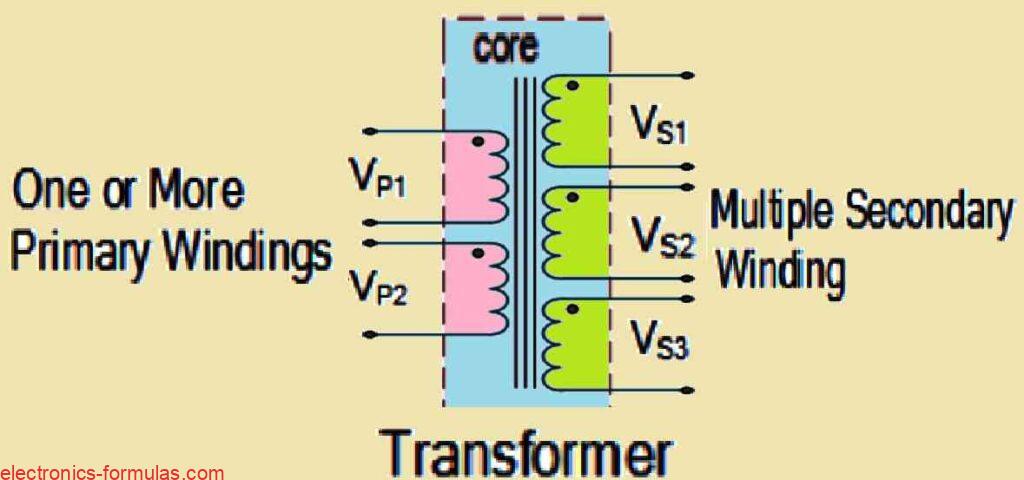

Talking about Multiple Winding Transformers these are a type of transformer that usually has one primary winding and then two or more secondary windings.

The cool thing about these transformers is that they can have multiple windings either on the primary side or the secondary side. Because of this feature we often call them Multiple Winding Transformers.

Now if we dive into how these transformers work we find that their basic principles are pretty much the same as those of a regular transformer.

The way we calculate the primary and secondary voltages, currents, and turns ratios does not change. However it is super important to pay attention to the voltage polarities for each coil winding.

To help with this we use something called the dot convention which helps us figure out whether the polarity of the windings is positive or negative when we are making connections.

These transformers are also known by other names like multi-coil transformers or multi-winding transformers.

They have multiple primary or secondary coils that are all placed on a single laminated core.

Plus they can work as either single-phase or three-phase transformers and throughout all of this their basic operating principles stay the same.

The Role of Multiple Winding Transformers

So basically Multiple Winding Transformers are devices that help with changing voltages.

This means that they can step up the voltage make it higher or step down the voltage make it lower or even do a bit of both across their different windings.

These transformers are pretty neat because they can have several secondary windings all on one single core and each of these windings can provide different voltage or current outputs.

Now let us get into how these transformers work. They operate based on a principle called mutual induction.

What this means is that each winding in a multiple winding transformer keeps a steady voltage for every turn of wire. Because of this the volt-ampere product which is basically a way to express the power remains the same across all the windings.

We can describe this relationship with the formula NP/NS equals VP/VS where NP is the number of turns on the primary side and NS is the number of turns on the secondary side and this turns ratio depends on what is supplied to the primary.

In many electronic circuits you will often find just one transformer being used to supply multiple lower voltage levels that different components in the circuit need.

A really common place where you will see multiple winding transformers used is in power supplies and triac switching converters.

Each secondary winding is kept electrically separate from all the others and also from the primary winding which allows each secondary coil to create a voltage that is proportional to how many turns it has.

Understanding Multiple Winding Transformer Configuration

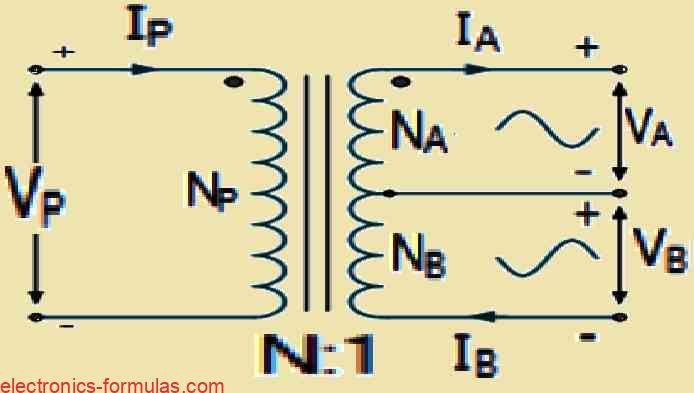

So in this illustration we have a classic example of what we call a “multiple winding transformer.” This type of transformer is really interesting because it has several separate secondary windings and each of these windings can provide different voltage levels.

The primary windings which are the ones that take in the input voltage can either work on their own or they can be combined together. When they are combined this allows the transformer to operate at higher supply voltages which is pretty handy.

Now let us talk about the secondary windings for a moment. These windings can be set-up in a bunch of different ways to create higher voltage or current outputs.

It is super important to point out that if you want to connect transformer windings in parallel which means connecting them side by side this is only allowed when the windings are electrically identical.

This means that their current ratings and voltage ratings have to match exactly in order for everything to work properly.

Understanding Dual Voltage Transformers

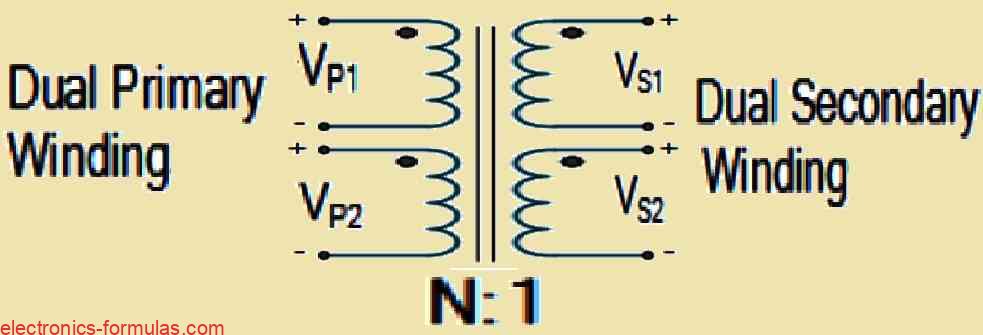

There are actually quite a few different types of multiple winding transformers out there and one interesting kind called the Dual Voltage Transformers.

These transformers are designed with two primary windings and each of these primary windings has the same voltage and current specifications.

But that is not all because they also come with two secondary windings that share identical voltage and current ratings as well.

These Dual Voltage Transformers are specifically engineered to handle a variety of applications which makes them really versatile.

The windings on these transformers can be connected in different ways either in series or in parallel. When you connect them in series it allows for higher primary voltages and when you connect them in parallel it helps you to get higher secondary currents.

These transformers are more frequently referred to as Dual Voltage Transformers

Transformer with Dual Primary & Dual Secondary Windings

In this setup the transformer has two main windings and two extra windings making a total of four.

It is really important to connect the primary and secondary windings correctly when using dual voltage transformers.

If they are hooked up the wrong way it can cause a short circuit which usually damages the transformer when it is turned on.

As we talked about before dual voltage transformers can be connected to different power sources with various voltage levels which is why they have the name “dual voltage transformers.”

For example the primary winding might be rated for 240/120V on one side and 12/24V on the other side.

To make this work both main windings need to be rated at 120V and each of the secondary windings should be rated at 12V.

The transformer must be wired correctly to make sure each primary winding receives the right voltage.

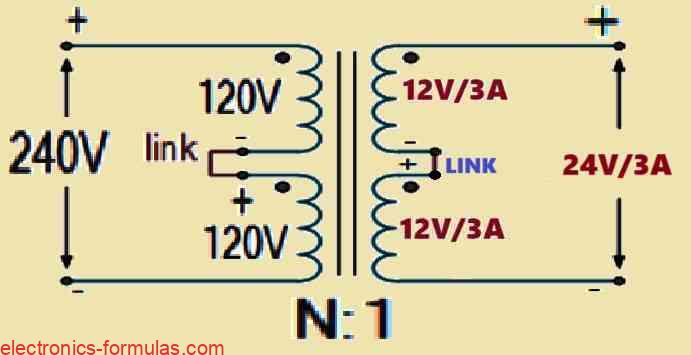

Take a look at the circuit shown below.

Transformer with Series Connected Secondary Winding

In this illustration that we are looking at, we have two primary windings and each of these windings is rated at 120 volts. These windings are set up in such a way that they are connected in series across a 240-volt power supply.

Since both of these windings are exactly the same so each one ends up experiencing a voltage drop of 120 volts. This means that the same primary current flows through both of them without any difference.

Now let us move on to the two secondary windings. Each of these secondary windings is rated at 12 volts and can handle up to 3 amps. Just like the primary windings these secondary windings are also connected in series.

Because they are connected in series the total voltage at the secondary terminals adds up to 24 volts. This total voltage is simply the sum of the voltages from each of the individual secondary windings.

Since the windings are arranged in series so the current remains steady as it flows through each winding. This results in a secondary current of 3 amps.

So when we look at this series-connected secondary configuration that we just described, we can see that the output is rated at 24 volts and 3 amps.

Now that we have covered this part, let us now take a closer look at the transformer that is connected in parallel below.

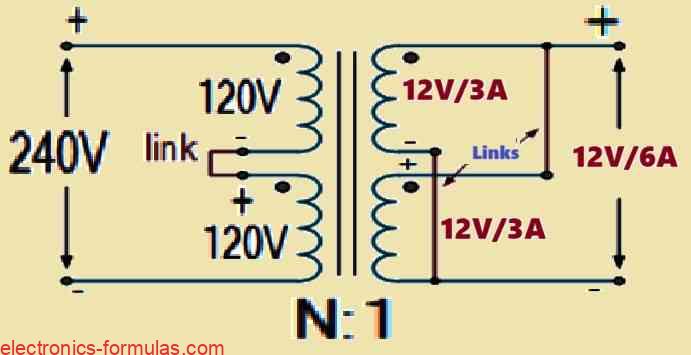

Transformer with Parallel Connected Secondary Winding

In this setup the two primary windings stay exactly the same as before, but now we have changed things up with the two secondary windings.

These secondary windings are now arranged in a parallel configuration based on how their dots are oriented.

Just to remind you each of these secondary windings is rated at 12 volts and can handle up to 3 amps.

Because they are connected in parallel so the secondary terminal voltage will remain at 12 volts, but the currents from both windings will combine together.

This means that in this parallel configuration we end up with an output that is rated at 12 volts but with a total current that becomes double at 3 + 3 = 6 amps.

It is really important to keep in mind that different dual voltage transformers might produce various levels of secondary voltage and current.

However the fundamental principle behind how they work stays consistent.

To get the desired voltage or current output it is essential that the secondary windings are connected correctly.

Now let us talk about dot orientation for transformer windings. This dot orientation is used to show which winding terminals are in phase with each other. For example if you connect two secondary windings that have opposing dot orientations then their magnetic flux will actually cancel each other out.

This can lead to either no output at all or it could even cause damage to the transformer.

Another interesting type of dual voltage transformer is called a Center-tap Transformer. This kind of transformer has a single secondary winding that is tapped right at its electrical midpoint.

Understanding Center Tap Transformers

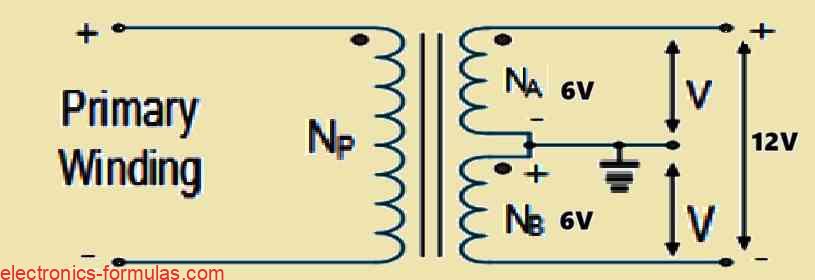

A center-tap transformer is specifically designed to give you two different secondary voltages which we can refer to as VA and VB.

These two voltages have a common connection point which makes this configuration quite unique. Because of this setup, the transformer creates what we call a two-phase, three-wire supply.

Now when we look at the secondary voltages produced by this transformer we find that they are actually the same and they are proportional to the supply voltage which we denote as VP.

This means that the amount of power flowing through each winding is equal. The actual voltages that come out across each of the secondary windings are determined the turns ratio which is a key factor in how transformers operate as shown in the following diagram.

VA = NA/NP * (VP)

VB = NB/NP * (VP)

What we see above is a typical example of a center-tap transformer. In this design the tapping point is located right in the middle of the secondary winding.

This setup provides a common connection point for two equal but opposite secondary voltages.

When the center tap is grounded, the output voltage VA will be positive when measured with respect to the ground. On the other hand, the voltage at the other secondary winding which we call VB, will be negative and opposite in nature. This means that these two voltages are 180 degrees out of phase with each other.

However there is a downside of using an ungrounded center-tap transformer. The issue is that it can create unbalanced voltages in the two secondary windings.

This happens because there can be unsymmetrical currents flowing through the common third connection due to unbalanced loads connected to the transformer.

Interestingly enough we can also create a center-tap transformer by utilizing the dual voltage transformer we discussed earlier. By connecting the secondary windings in series we can use the center link as the tap point just like we have shown in the illustration.

If suppose each of the secondary outputs provides a voltage of 6V then when they are connected this way, the total output voltage from the secondary winding will be equal to 12V as illustrated below.

Using Multiple Winding Transformers to Create Center-Tap Transformers

Multiple Winding Transformers are really important in electrical and electronic circuits. They are super flexible because they can give out different secondary voltages to match the needs of different loads.

You can set up their windings in series or parallel, depending on what you need. This means that you can get higher voltages or more current when you need it.

Also if you connect the secondary windings in series then you can build the center-tapped transformers which adds even more cool features to the design.

References:

Leave a Reply